700×300 H beam Q235B and Q345B beam, I beam Steel structure Universal Column

1. Simple instruction:

H-beam is a kind of economical section and high-efficiency section with more optimized cross-sectional area distribution and

more reasonable strength-to-weight ratio. It is named after its section is the same as the English letter “H”. Since all parts of

the H-beam are arranged at right angles, the H-beam has the advantages of strong bending resistance, simple construction,

cost saving and light weight in all directions, and has been widely used.

2. Chemical Composition

| Grade | Chemical Composition (%) | ||||

| C | Si | Mn | P | S | |

| Q235B | ≤0.20 | ≤0.35 | ≤1.40 | ≤0.045 | ≤0.045 |

| Q345B | ≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.035 |

| Q345C | ≤0.20 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.030 |

| Q345D | ≤0.18 | ≤0.50 | ≤1.70 | ≤0.035 | ≤0.025 |

3. Mechanical Properties

| Grade | Mechanical Property | ||

| Yield Strength (N/mm2)/(Mpa) | Tensile Strength (N/mm2)/(Mpa) | Elongtation (%) | |

| Q235B | ≥235 | 370-500 | ≥26 |

| Q345B | 345 | 470-630 | ≥20 |

| Q345C | 345 | 470-630 | ≥21 |

| Q345D | 345 | 470-630 | ≥21 |

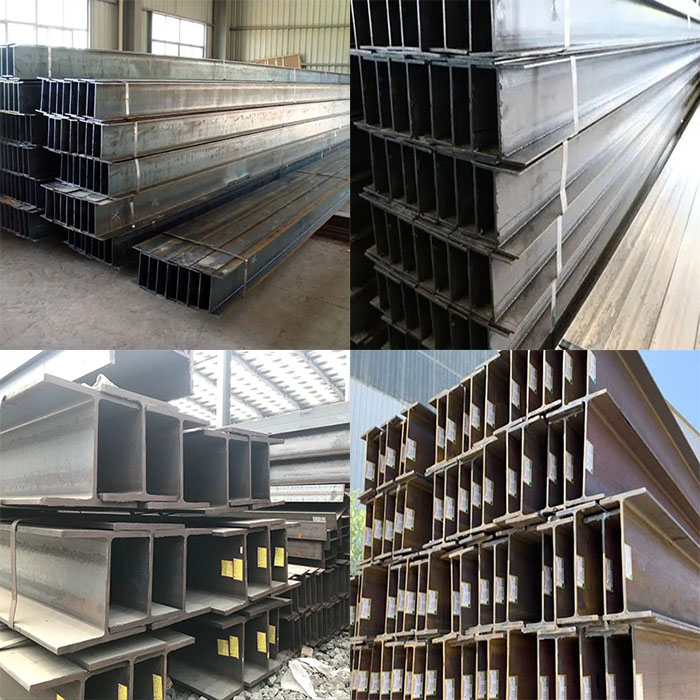

4. Picture Show:

5. Further treatment:

6. High Frequence Welded H beam:

High-frequency current is used to locally heat the metal surface, and it is welded under the action of external force, without

any welding wire or flux, and can be continuously produced in large quantities.

1)Wide range of specifications (section size). Height, web, flange thickness and flange width can be selected according to customer

requirements for steel plate welding. It can be used as a variety other than the standard of hot-rolled H-beam.

2) Choose a variety of steel types. Hot-rolled H-beams are mainly Q235B and Q345B. When small batches of special steel grades are

required, the production plant cannot produce them. Welding can choose steel plate as needed.

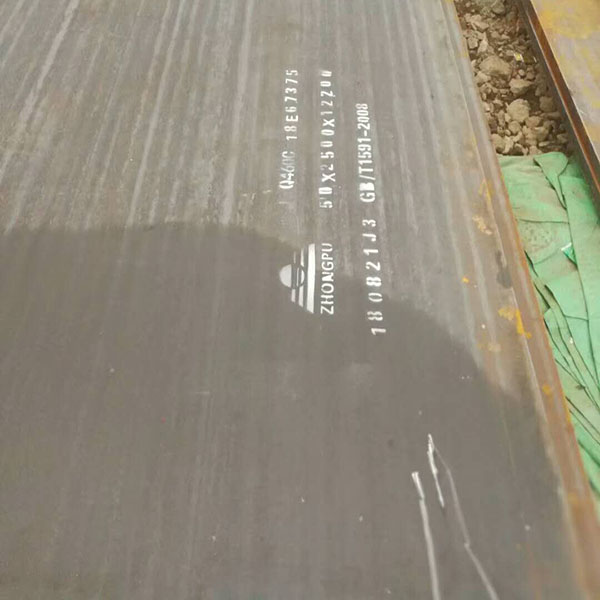

3)The product has high precision and good surface quality. Due to the high precision and good surface quality of the steel plate product,

the H precision after welding is also high and the surface quality is also good. The thickness deviation of steel plates (used for welding H-beams)

is generally a few tenths of a millimeter to a few tenths of a millimeter, while the thickness deviation of hot-rolled H-beams is a few tenths of a

millimeter to 1 millimeter, which is nearly 10 times the difference.

4) Stable performance and good internal organization. Since the production of steel plates from smelting to continuous casting to rolling is

higher than that of hot-rolled H-beams ) indicators are reliable and stable.

5) It is easy to have welding defects. Although there are many advantages mentioned above, due to the welding forming, there is welding residual

thermal stress in the welding area, the structure of the welding area is different, and there is structural stress, which is prone to welding defects.

With the continuous improvement of welding level and heat treatment level, these disadvantages are gradually reduced. Today, high-quality welded

H-beams have been used in various fields including military industry and aerospace.